How German Food & Beverage Manufacturers Choose Freeze-Dried Fruit Powder

12 月-28-2025

How German Food & Beverage Manufacturers Choose Freeze-Dried Fruit Powder

What matters in Germany is not just “natural fruit taste”, but repeatable performance: solubility, colour stability, microbiological control, and documentation that survives an audit without drama.

Why Germany Buys Fruit Powder Differently

German buyers tend to purchase freeze-dried fruit powder with a manufacturing mindset. They care about taste, yes—but they care even more about whether the powder behaves predictably across batches, equipment, and shelf life. A great sample that fails in scale-up is useless. A powder that performs reliably in production becomes a long-term supply relationship.

For brands selling into Germany, freeze-dried fruit powder is often used to support “real fruit” positioning while keeping formulations clean and functional. You’ll see it in powdered drinks, nutrition mixes, yoghurt flavour systems, bakery dry mixes, and confectionery where a stable fruit note is needed without adding excess moisture.

If your buyer is still deciding which fruit powder format fits their product pipeline, the fastest way to orient them is your Freeze-Dried Fruit Powder collection, then narrowing by application.

The German Buyer’s Checklist

Below is the evaluation logic you’ll see repeatedly in German procurement and R&D conversations.

1) Solubility and Dispersion

Many German applications require uniform dispersion—especially instant beverages, nutrition powders, and functional mixes. Buyers will test how quickly the powder wets and disperses, whether it floats, whether it clumps, and how it behaves in cold vs warm liquid.

They also check whether the powder leaves sediment, because sediment changes consumer perception even when flavour is acceptable. For premium beverage mixes, mouthfeel matters as much as taste.

2) Flavour Authenticity Without Off-Notes

German product teams typically chase a clean, true-to-fruit flavour rather than a candy-like profile. They’ll evaluate the powder both alone and inside the full formulation (acid system, sweetener system, proteins, fibres, or dairy matrix). Some fruit notes collapse when proteins are added; others become harsh when acids are high.

A practical expectation is consistency: the flavour should not swing between harvest seasons or lots. That’s why buyers ask about raw material sourcing and process control, not only lab results.

3) Colour Stability in Real Formulas

Colour is tested in the final product context. For example, in yoghurt systems the powder must hold colour without browning. In beverages, it should not fade quickly under light or shift under pH stress.

German brands often prefer colour that looks “naturally derived,” but they still demand stability that survives transport, retail lighting, and normal shelf life.

4) Particle Size and Flowability

Even when buyers don’t say it directly, they care about production flow. A powder that bridges in a hopper, dusts excessively, or feeds inconsistently becomes a factory headache.

Typical checks include whether the powder flows smoothly, whether it compacts during shipping, and whether it creates dust issues that complicate hygiene and housekeeping.

5) Microbiological Control and Traceability

Germany is documentation-heavy. Buyers want confidence in traceability and microbiological control. The expectation is not just “safe,” but “audit-ready,” meaning your documentation and lot tracking should be fast, consistent, and complete.

To support this story without overwhelming the article, link capability context naturally through About Us and let serious buyers move to sampling through Contact Us.

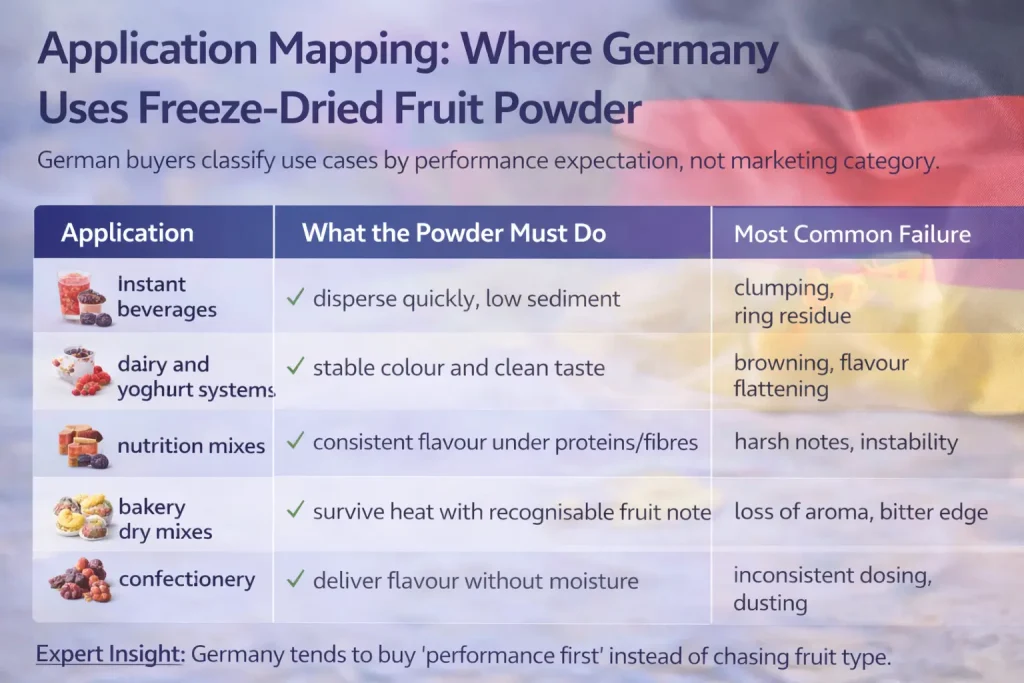

Application Mapping: Where Germany Uses Freeze-Dried Fruit Powder

German buyers often classify use cases by how the powder must perform, not by marketing category.

| Application | What the Powder Must Do | Most Common Failure |

|---|---|---|

| instant beverages | disperse quickly, low sediment | clumping, ring residue |

| dairy and yoghurt systems | stable colour and clean taste | browning, flavour flattening |

| nutrition mixes | consistent flavour under proteins/fibres | harsh notes, instability |

| bakery dry mixes | survive heat with recognisable fruit note | loss of aroma, bitter edge |

| confectionery | deliver flavour without moisture | inconsistent dosing, dusting |

This table is useful because it stops buyers from choosing a powder based only on fruit type. Germany often buys “performance first.”

What German R&D Teams Ask During Sampling

When a German buyer requests samples, they usually want a clear test plan. If you give them a sample but no guidance, they will test it anyway—just not in a way that makes you look good.

A strong sampling approach includes recommended dosage range, suggested dispersion method, and the best “stress test” conditions (pH range, temperature, protein system, standing time). This makes your powder easier to approve because it reduces uncertainty.

If you want to place supporting evaluation methods somewhere on your site, direct technical readers to the Knowledge hub as the home for application notes and testing logic.

Ingredient Storytelling That Works in Germany

German brands often want a story that sounds factual, not promotional. They prefer practical evidence: how the ingredient is processed, why it retains aroma, how it supports shelf stability, and how supply stays consistent.

This is where company fundamentals matter. Fujian Lixing Foods Co., Ltd. can credibly position manufacturing scale, R&D capability, and export experience as a stability signal rather than a sales pitch—especially when the buyer is choosing a long-term supplier.

Expert Insights

A German beverage formulator’s view: the best fruit powder is the one that stays stable when the formula gets complicated. Protein systems, acids, and fibre blends can change everything. If the powder performs only in water tests, it is not production-ready.

A procurement manager’s view: audit readiness reduces risk. When traceability and documentation arrive quickly and consistently, the buyer feels protected—and scaling the contract becomes easier internally.

A quality lead’s view: most “quality issues” are actually consistency issues. German brands value predictable performance more than a single impressive batch. The supplier who controls variability wins.

Using Plant Powders to Build a Broader Product Line

German buyers often expand from fruit powders to other plant-based powders once a supplier relationship is trusted. This is where you can introduce adjacent products naturally, without switching the article into a catalogue.

For example, when discussing product development for functional blends or savoury bases, it’s natural to reference plant powders like Freeze-Dried Corn Powder as part of broader ingredient development.

How to Move a German Buyer from Interest to a Real RFQ

The fastest way to convert interest into a qualified request is to ask for the details German teams already track:

Product format (beverage, yoghurt, mix, bakery), target dosage range, dispersion method, pH range, any protein/fibre system, required shelf stability behaviour, and preferred pack format. Once you have that, a sampling plan becomes meaningful rather than random.

The clean next step is a short inquiry through Contact Us that includes application details so you can propose the right powder options and testing guidance.

Conclusion

Germany buys freeze-dried fruit powder with a manufacturing lens: solubility, stability, batch consistency, and audit-ready control matter as much as taste. When suppliers support R&D with realistic application testing, provide predictable powder behaviour, and maintain strong traceability discipline, German buyers are more willing to scale from trial orders into long-term supply. The win condition is simple: make the ingredient easy to trust in production, not only impressive in a sample cup.

FAQ

What is the best way to test freeze-dried fruit powder for German beverage applications?

Test dispersion in the real formula, not only in water. Include cold and warm mixing, standing time, and typical pH conditions used in the product.

Why does fruit powder sometimes clump in instant drink mixes?

Clumping usually comes from poor wetting or moisture exposure during handling. Mixing method, powder characteristics, and storage conditions all influence this.

Can freeze-dried fruit powder be used in yoghurt and dairy products?

Yes. The key is colour and flavour stability in a dairy matrix. Buyers typically test browning risk and flavour clarity over time.

How do manufacturers choose particle size for fruit powder?

They match particle size to the equipment and application. Flowability, dusting control, and dispersion speed are practical decision factors.

What information should a buyer include when requesting samples?

Application type, dosage range, mixing method, pH range, any protein or fibre system, and the performance expectations such as sediment tolerance and colour stability.

How do suppliers support documentation expectations for German buyers?

By providing consistent lot tracking, traceability, and quick responses to standard documentation requests. This reduces audit friction and speeds approvals.

Can freeze-dried fruit powder support clean-label positioning in Germany?

It often can, because it delivers fruit character without adding moisture-heavy fruit preparations. Final claims depend on the full formula and local labelling rules.