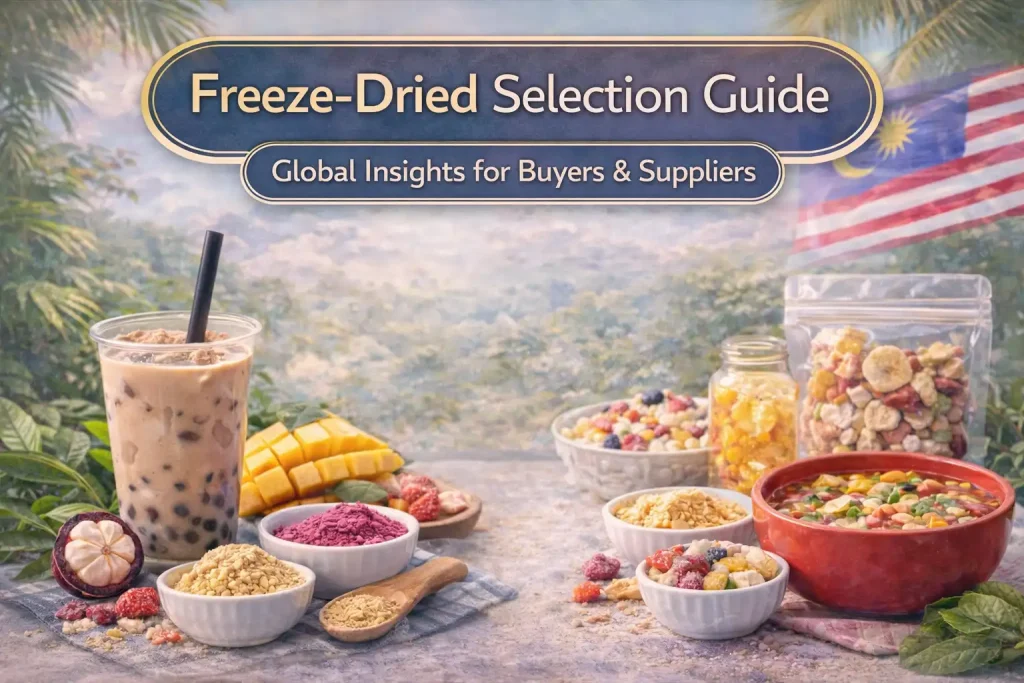

How Malaysian Brands Choose Freeze-Dried Ingredients for Halal-Friendly Formulas, Tropical Flavour, and Clean Rehydration

12 月-28-2025

How Malaysian Brands Choose Freeze-Dried Ingredients for Halal-Friendly Formulas, Tropical Flavour, and Clean Rehydration

From milk tea and fruit drinks to instant soups and bakery mixes—Malaysia buys what performs consistently in real production.

Malaysia is a market where ingredient decisions are rarely “just taste.” Product teams typically balance halal expectations, tropical flavour preferences, and factory practicality—especially for beverages, instant mixes, bakery, and convenience foods. That’s exactly why freeze-dried fruits, vegetables, and powders keep gaining share: they deliver strong natural character with stable handling, precise dosing, and predictable rehydration.

This guide breaks down how Malaysian brands usually choose freeze-dried ingredients, what they test first, and how to move from shortlist to repeat orders without wasting weeks on avoidable re-trials.

What Malaysia Prioritises When Buying Freeze-Dried Ingredients

Malaysian buyers tend to optimise for three things:

They want flavour that feels “real” (especially tropical profiles), they need stability in warm/humid storage environments, and they want specs that behave consistently in their target system—hot soups, chilled drinks, dairy beverages, bakery premixes, or snack blends. Halal readiness matters too, because even when a product is not labelled halal, brands often prefer suppliers that can support halal-aligned documentation and clean processing expectations.

If a buyer is still exploring what freeze-dried categories you offer, the simplest starting point is your main ingredient portfolio under Dried Foods.

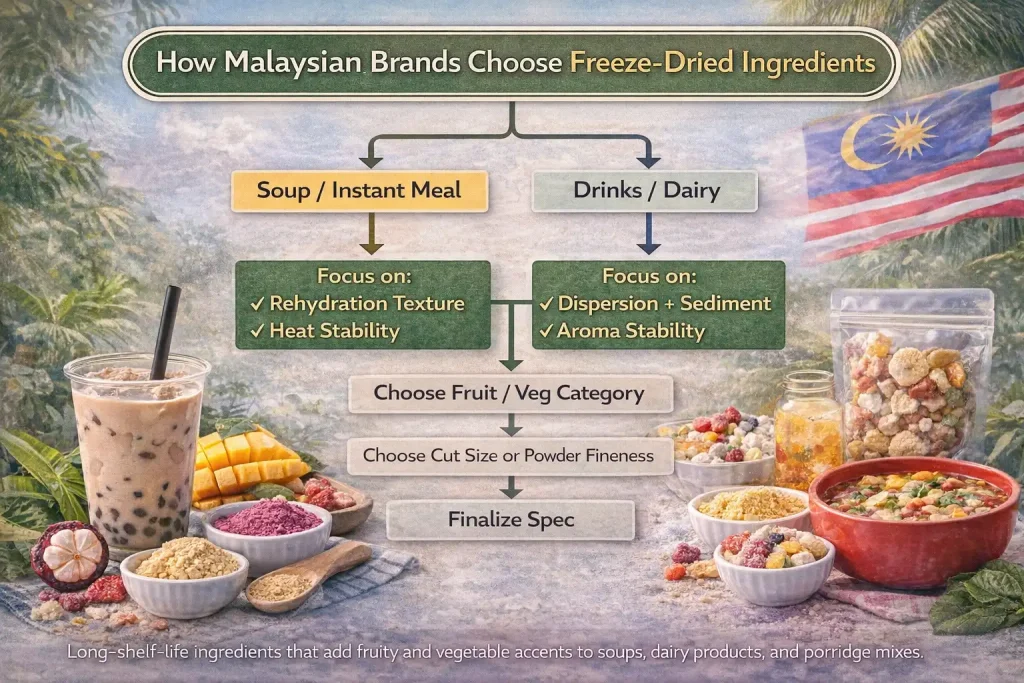

Step 1: Choose the Product System First (Hot vs Cold)

Malaysia’s use cases cluster naturally into “hot systems” and “cold systems.” This one decision saves a lot of time.

Hot systems include instant soups, noodle meals, porridge mixes, and hot bakery fillings. Cold systems include milk tea, fruit drinks, yogurt-style products, and ready-to-mix beverage powders.

A practical decision tree looks like this:

| System Type | Typical Malaysian Products | Best Format | First Test |

|---|---|---|---|

| Hot system | Instant soup, noodle cup, porridge mix | Pieces / dices, some powders | Rehydration texture + heat stability |

| Cold system | Milk tea, fruit drinks, yogurt blends | Powders (and small inclusions) | Dispersion + sediment + aroma stability |

If the buyer’s development is mostly powder-based, direct them to your dedicated powder range using anchored text: <a href=”https://www.lixingfdfoods.com/freeze-dried-fruit-powder”>Freeze-Dried Fruit Powder</a>.

Step 2: Decide Between Pieces and Powder (Malaysia’s “Speed vs Experience” Choice)

In Malaysia, this choice is often about consumer experience.

Pieces are chosen when the ingredient must be seen or felt—fruit-tea inclusions, dessert toppings, snack mixes, or premium instant soups. Buyers care about how the pieces rehydrate and whether colour and shape stay attractive after storage.

Powders are chosen when the ingredient must disappear into the product—milk tea, fruit drinks, bakery premixes, seasoning blends, functional mixes. Buyers care about flowability, dispersion, and whether the powder clumps in humid conditions.

Step 3: Malaysia’s Most Common Applications (And What “Good” Looks Like)

Fruit Drinks and Fruit-Tea Hybrids

Malaysia’s beverage market loves tropical flavour. Freeze-dried fruit powder works well because it brings aroma and flavour identity without adding liquid fruit complexity.

If a buyer asks for “ideas that work in real menus,” it’s helpful to reference usage-driven content naturally. Citrus is a good example for drinks and desserts, so this is a clean contextual link: Uses of Freeze-Dried Lemon Slices.

Milk Tea and Tea-Based Drinks

Tea-based beverages are a frequent backbone for product innovation. A stable tea base plus fruit direction can help brands build seasonal SKUs fast.

If the buyer wants a concrete tea-base example, a relevant product reference is Spray-Dried Oolong Tea Instant Powder. If they want to browse the full range of tea and plant extracts, point them to Tea & Plant Extract Products.

Instant Soups and Convenience Meals

Freeze-dried vegetables can upgrade “real food perception” in instant soups and meal cups while keeping shelf stability. Buyers typically focus on rehydration behaviour and how ingredients perform with oil and seasoning systems.

For a buyer who needs proof that this is a mainstream direction, it helps to reference a relevant educational page: Freeze-Dried Vegetable Soup Packets.

Bakery Premixes and Dessert Formulas

Fruit powders can add clean flavour identity to premixes and dessert formulations. Malaysian product teams usually evaluate aroma stability after storage and whether the powder distributes evenly without patchiness.

Step 4: The “Humidity Reality Check” Malaysia Always Runs

Malaysia’s environment makes moisture pickup a practical risk. Great powders can still fail if they cake, clump, or lose aroma during handling.

What Malaysian buyers commonly validate:

-

Dispersion speed in cold water and in milk-based systems

-

Sediment behaviour after standing (especially for ready-to-drink concepts)

-

Clumping resistance during real batching

-

Aroma stability after storage under warm conditions

-

Consistency across lots (colour, aroma, particle behaviour)

For general shelf-life considerations, this supporting reference can be used naturally when buyers ask “how long will it hold up”: Shelf Life of Dried Fruits.

Expert Insights

A beverage formulator’s view: in milk tea and fruit drinks, the ingredient doesn’t just add flavour—it controls the whole experience. The fastest path to success is choosing powders that disperse smoothly and keep aroma bright after storage, then confirming behaviour in the brand’s real mixing method.

A convenience-food developer’s view: in instant soups and meal formats, rehydration is the product. Consumers don’t forgive tough vegetables or uneven bite. Choosing the right cut size and testing realistic rehydration time points is what prevents bad reviews later.

A quality manager’s view: the difference between “trial order” and “repeat order” is consistency. When lots behave the same, approvals move faster, internal re-testing decreases, and purchasing becomes confident.

Step 5: How Buyers Shortlist Specs Faster

A simple shortlist approach that works well in Malaysia:

First, lock the system type (hot vs cold). Next, lock the format (pieces vs powder). Then choose the fruit/vegetable direction and run 2–3 focused tests aligned to the product reality. This prevents teams from doing broad, expensive testing that doesn’t predict real outcomes.

If buyers want to understand your company capacity, export experience, and certifications context before starting trials, send them to About Us. If they want to request specs or samples, route to Contact Us. If they prefer learning content first, use Knowledge.

Conclusion

Malaysia buys freeze-dried ingredients for performance, not hype. The best selection method is application-first: determine whether the product is a hot or cold system, choose pieces or powder accordingly, and validate the few tests that actually predict success—rehydration texture for hot systems, dispersion and sediment behaviour for cold systems, plus humidity resistance and lot consistency for both. When those fundamentals are right, Malaysian brands move quickly from sampling to stable repeat orders across beverages, instant foods, bakery, and dessert innovation.

FAQ

Why do Malaysian beverage brands prefer freeze-dried fruit powder for cold drinks?

Because it supports precise dosing and consistent flavour delivery, while helping product teams control dispersion and aroma stability in chilled systems.

What is the biggest issue for powders in Malaysia’s climate?

Moisture pickup, which can lead to caking, clumping during batching, and weaker aroma performance after storage.

How do I choose between fruit pieces and fruit powder?

Choose pieces when you want visible inclusions and texture cues. Choose powder when you need uniform flavour and smooth processing in mixes and premixes.

What should be tested first for milk tea and dairy beverages?

Dispersion speed, sediment behaviour after standing, and aroma stability after storage are usually the fastest indicators of real performance.

What should be tested first for soups and instant meals?

Rehydration texture at realistic time points, heat stability, and compatibility with oil and seasoning systems.

Why does aroma sometimes fade after storage?

Aroma can weaken if the ingredient absorbs moisture or if storage conditions fluctuate. Stable specs and consistent handling reduce that risk.

What information helps suppliers recommend the right spec quickly?

The application type, hot or cold preparation, target flavour intensity, desired particle size or powder fineness, and expected storage conditions.

Where should buyers go to request samples or specifications?

Use the Contact Us page to request specifications and discuss application fit.