How UK Food Brands Choose Freeze-Dried Fruits for Premium Snacks and Bakery

12 月-28-2025

How UK Food Brands Choose Freeze-Dried Fruits for Premium Snacks and Bakery

An ingredient-selection playbook for bright flavour, clean label positioning, and reliable performance in real production—so your “premium” claim holds up in every bite.

Why UK Buyers Treat Freeze-Dried Fruit as a Brand Ingredient

In the UK, freeze-dried fruit isn’t just a flavour add-on. For many snack brands, bakeries, and “better-for-you” product lines, it functions like a signature: it affects colour, aroma lift, texture, and the customer’s first impression when they open the pack. That’s why UK buyers typically evaluate freeze-dried fruit with two questions in mind: will it make the product taste and look premium, and will it behave consistently in production and on shelf?

The UK market also has a sharp ear for “clean label” storytelling. If the ingredient performs well, it supports simple positioning. If it performs poorly—dull flavour, soggy inclusions, inconsistent pieces—no amount of marketing copy can rescue it.

To explore formats and options across categories, it’s natural to start from Dried Foods and narrow down by end use.

Step One: Define the Product Format, Because It Changes Everything

UK buyers usually start by clarifying the product format, because freeze-dried fruit behaves very differently depending on moisture, fat, and processing temperature.

A granola or cereal inclusion needs fruit that stays crisp and aromatic. A chocolate-coated snack needs fruit that won’t create moisture migration issues. A cookie inclusion needs fruit that survives baking without turning bitter or losing identity. A bakery topping needs fruit that looks vibrant on day one and still looks appetising after the product sits in a display case.

When you define format first, you can match fruit types and cut styles to the job, rather than trying to force one ingredient to work everywhere.

The UK Checklist: What “Premium Performance” Means in Practice

UK buyers often use a practical checklist that focuses on consumer experience and production stability.

Aroma Lift and “First Open” Impact

Many UK snack brands win on aroma. When a consumer opens the pack, the fruit note should feel real, not candy-like or flat. Freeze-dried fruit can deliver that punch, but only if the raw material quality is strong and the drying process is controlled.

A common evaluation method is simple: compare aroma intensity at the same dosage across candidate lots, then repeat after storage. If the aroma drops quickly, the product loses its premium edge on shelf.

Texture: Crisp Where It Should Be Crisp

Texture expectations differ by application. For granola and crisp snacks, buyers want a clean crunch without a hard “tooth-breaking” bite. For baked goods, they want inclusions that soften slightly but still feel like fruit, not like crumbs.

If the fruit absorbs moisture too easily, it can turn chewy in a cereal pack or cause local soft spots in baked products. UK buyers pay attention to this because texture complaints can kill repeat purchase.

Visual Identity: Pieces Must Look Like Fruit

UK consumers read quality visually. Fruit that looks faded or fragmented can make a product feel cheap, even if the flavour is acceptable. Buyers therefore evaluate piece integrity, cut consistency, and colour brightness.

For premium SKUs, buyers also care about uniformity: the bag should not contain mostly dust at the bottom and oversized chunks at the top. That’s not just a visual issue—it creates dosing inconsistency, which becomes flavour inconsistency.

Taste Clarity: No Bitter Back-End

Some freeze-dried fruits can show bitterness depending on variety, ripeness, or processing. In UK bakery and snack applications, a bitter finish is especially damaging because it clashes with butter notes, cocoa notes, or cereal bases.

A reliable test is to evaluate the fruit both alone and inside the real matrix—chocolate, oat base, shortbread base—because the matrix can amplify defects that taste mild on their own.

Matching Fruit Formats to UK Snack and Bakery Use Cases

UK buyers usually choose between formats like slices, dices, granules, and powders depending on where the fruit sits in the product.

In granola or cereal clusters, smaller pieces distribute evenly and create consistent flavour across servings. In premium bakery toppings, larger pieces or slices create visual appeal and “premium cues.” In fillings, powders and fine granules offer predictable flavour without the textural risk of larger pieces.

If you’re building a portfolio story around visible fruit identity, you can naturally reference signature ingredients like Freeze-Dried Mangosteen as an example of how distinctive fruit character supports premium positioning.

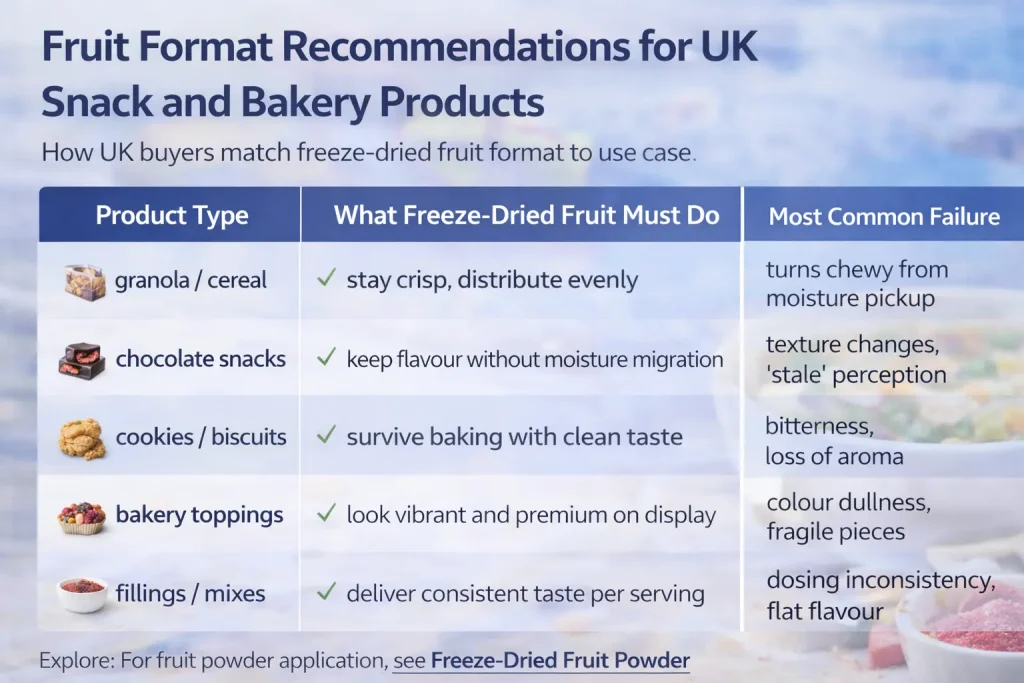

A Simple Table UK Buyers Use to Avoid Format Mistakes

This is the kind of clarity UK product teams like—simple and practical:

| Product Type | What Freeze-Dried Fruit Must Do | Most Common Failure |

|---|---|---|

| granola / cereal | stay crisp, distribute evenly | turns chewy from moisture pickup |

| chocolate snacks | keep flavour without moisture migration | texture changes, “stale” perception |

| cookies / biscuits | survive baking with clean taste | bitterness, loss of aroma |

| bakery toppings | look vibrant and premium on display | colour dullness, fragile pieces |

| fillings / mixes | deliver consistent taste per serving | dosing inconsistency, flat flavour |

Moisture Management: The Hidden Risk in UK Retail

UK buyers are very sensitive to moisture behaviour because it affects shelf life perception. Even if the product remains safe, a texture change is enough to trigger complaints.

Freeze-dried fruit is naturally porous. That’s why packaging, storage humidity, and how the fruit is handled on line matter almost as much as the fruit itself. Many “ingredient problems” are actually handling problems—open exposure in humid rooms, slow line speeds, or repacking steps that let the fruit absorb moisture.

If you want to support the buyer’s thinking with related reading inside your site ecosystem, a natural “storage expectation” reference can point to Shelf life guidance for dried foods.

Powder vs Pieces in UK Product Development

UK snack and bakery teams often use both. Pieces deliver visual identity and texture. Powders deliver consistent flavour distribution and can support “real fruit” positioning without adding chewiness.

Powders are especially useful when you need uniform flavour at low dosage or when you want to avoid the “random fruit distribution” problem in baked goods. If you want to connect the reader to your fruit powder capabilities, the clean internal route is Freeze-Dried Fruit Powder.

Expert Insights

A UK product developer’s view: the best freeze-dried fruit is the one that stays “true” inside the real recipe. It’s easy to fall in love with a fruit sample on its own, then discover it disappears in oats, cocoa, or butter-heavy matrices. Always test in the finished base.

A technical buyer’s view: uniformity is not cosmetic—it’s operational stability. When cut sizes vary too much, dosing varies. When dosing varies, flavour varies. And when flavour varies, the brand loses trust.

A quality manager’s view: moisture exposure is the silent destroyer. If you treat freeze-dried fruit like a sensitive ingredient—sealed handling, controlled storage, minimal open time—you reduce texture drift and stop most shelf-life complaints before they happen.

How Fujian Lixing Fits UK Buyer Expectations

Fujian Lixing Foods Co., Ltd. manufactures vacuum freeze-dried fruits and vegetables, instant tea powder and tea concentrate, and other plant extracts. For UK buyers, the practical value is the ability to support both premium positioning and stable production: consistent formats, application-fit options, and a capability base that can scale with long-term procurement.

When you want buyers to understand manufacturing strength and certifications in a professional way, link naturally through About Us. When they are ready to discuss samples and specifications, the best next step is Contact Us so the request includes the product format, target texture, cut preference, and shelf-life expectations.

If you’d like to guide buyers into technical reading without overwhelming the article, route them to Knowledge as the place for application notes and selection logic.

Conclusion

UK food brands choose freeze-dried fruits the way they choose signature ingredients: by testing aroma lift, texture behaviour, visual identity, and taste clarity inside the real product matrix, not just in a sample cup. The most reliable selections are the ones that remain crisp where they should, stay visually appetising, avoid bitter back-notes, and hold performance through packaging and storage realities. When brands evaluate moisture sensitivity and uniformity as part of quality, they protect both consumer experience and production stability—making “premium” a repeatable outcome, not a lucky batch.

FAQ

How do UK snack brands test freeze-dried fruit for granola or cereal?

They test crispness and aroma in the finished cereal base, then repeat after storage to confirm the fruit does not turn chewy or lose impact.

Why does freeze-dried fruit sometimes become chewy inside packaged snacks?

It usually absorbs moisture from the surrounding product or the environment. Sensitive handling and packaging strategy reduce moisture pickup.

Is freeze-dried fruit suitable for baking in cookies and biscuits?

Yes, but it must be tested in the real bake cycle because some fruits can lose aroma, darken, or develop bitterness depending on temperature and recipe base.

How do buyers choose between fruit pieces and fruit powder?

Pieces deliver visual identity and texture, while powder delivers consistent flavour distribution. Many brands combine both for balance.

What matters most for “premium” visual identity in bakery toppings?

Colour brightness, piece integrity, and cut consistency matter most because consumers judge quality immediately by appearance.

How should brands request samples for snack and bakery development?

They should specify product type, processing method, target texture, preferred cut style, dosage range, and storage conditions so the supplier can match options accurately.

Are citrus fruits like lemon used differently in UK product development?

Often yes. Citrus can brighten flavour systems and work well in bakery and snack blends when balanced properly. For product inspiration, see uses of freeze-dried lemon slices.