US Beverage Brands’ Checklist for Choosing Freeze-Dried Fruit Powder

12 月-28-2025

US Beverage Brands’ Checklist for Choosing Freeze-Dried Fruit Powder

What to test for clean dissolve, stable natural colour, and consistent flavour under real mixing conditions—so your drink tastes the same in every batch, every warehouse, every market.

Why US Brands Are Rebuilding Their Fruit Systems

In the US beverage market, “fruit flavour” isn’t enough anymore. Buyers and formulators are chasing a cleaner, more authentic fruit experience, and they need it to behave predictably in production—whether the product is a stick pack, a smoothie blend, a functional drink mix, or a café-style fruit tea. That’s exactly where freeze-dried fruit powder earns attention: it can deliver bright aroma and natural colour while supporting stable storage when handled correctly.

But here’s the part people learn the hard way. Freeze-dried fruit powder is not a single “commodity ingredient.” Two powders that look identical in the bag can behave completely differently in cold water, in a high-shear mixer, or after sitting for 20 minutes in a customer’s cup. This checklist is designed to help US beverage brands choose powders that dissolve cleanly, hold colour, and keep flavour consistent—without creating headaches for production teams or customer support.

If you want to explore the category context before narrowing down formats, start with Freeze-Dried Fruit Powder.

Start With the Beverage Reality, Not the Ingredient Fantasy

Before you evaluate powders, define the “real life” your product must survive. A powder that works in warm lab water may fail completely in iced water with a quick shake. A powder that behaves in a blender may look gritty in a simple stir. US consumers are ruthless about this, especially in products marketed as premium, functional, or “clean label.”

Your evaluation should mirror the final consumer and production conditions: cold dissolve or hot dissolve, water hardness, mixing energy, standing time, and intended acidity level. Once those are defined, you can judge powders by performance instead of marketing adjectives.

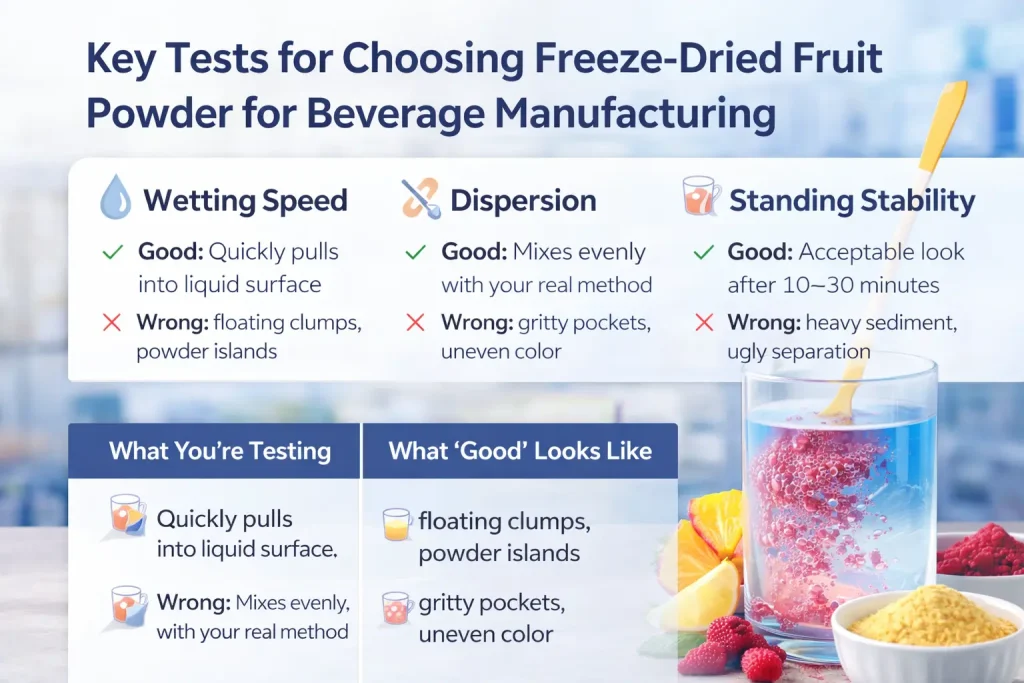

Clean Dissolve: The Three Tests That Predict Complaints

Most beverage complaints trace back to mouthfeel and appearance. “Gritty.” “Sandy.” “Settles too fast.” “Clumps on top.” Those aren’t branding issues; they’re selection issues.

Wetting Speed

Wetting is the first battle. If powder resists wetting, it floats, forms islands, and creates clumps that never fully break. Fast wetting usually translates into easier consumer prep and fewer “it didn’t mix” reviews.

Dispersion

Dispersion means how evenly the powder spreads through the drink with the mixing method you expect the consumer to use. A powder might eventually disperse under strong blending, but if your product is a stick pack, “eventually” is not good enough.

Standing Stability

Even a well-mixed drink can look terrible after it sits for 10–30 minutes. US retail and foodservice both face this issue: customers take drinks to-go, put them in cupholders, and come back to a visible layer at the bottom. A good powder doesn’t have to be perfectly “clear,” but it should settle in a way that doesn’t feel like a defect.

A simple performance table makes decision-making easier:

| What You’re Testing | What “Good” Looks Like | What Usually Goes Wrong |

|---|---|---|

| Wetting speed | quickly pulls into liquid surface | floating clumps, powder islands |

| Dispersion | mixes evenly with your real method | gritty pockets, uneven colour |

| Standing stability | acceptable look after 10–30 minutes | heavy sediment, ugly separation |

Colour That Stays Attractive Instead of Turning “Sad”

Natural colour is a major reason brands choose fruit powders, but colour stability depends on your formula and storage reality. Acid level, light exposure, and temperature swings can all change how colour presents over time. If your drink is sold in clear packaging or served in transparent cups, colour drift is not a small issue—it is the product experience.

When you evaluate colour, do it in the finished formula at real concentration, then check it again after storage under realistic conditions. If you’re building fruit-tea blends, test colour both in water and in tea base, because tea solids can shift colour perception and make a fruit note look dull.

If your development work includes tea-based systems, it’s useful to reference the ingredient family through Tea & Plant Extract Products.

Flavour Consistency: Don’t Chase “Strong,” Chase “Repeatable”

The goal is not maximum punch; it’s a consistent flavour signature across production runs. In US markets, repeat purchase is everything. If one batch tastes bright and another batch tastes flat, consumers don’t troubleshoot—they abandon.

A strong selection process focuses on aroma lift, clean finish, and predictable intensity at target dosage. If you plan to pair fruit powders with tea bases, define which note leads. Tea-forward and fruit-forward products use different balancing logic, and powders that feel perfect in one direction can clash in the other.

Storage and Humidity: The Silent Factor That Breaks Good Powders

Humidity is the enemy of powder performance. It affects flowability, clumping, and dose consistency. US distribution conditions vary widely, and humidity exposure can happen at any stage—warehouse, repacking, foodservice handling, or consumer use after opening.

If you want fewer production surprises, treat humidity behaviour as part of ingredient performance. A powder that clumps under normal handling will create inconsistent dosing, which turns into inconsistent flavour and unstable customer experience.

A helpful way to explain this to buyers is to connect powder behaviour to operational risk: if the powder cakes or bridges in hoppers, your line slows; if it clumps in the cup, your brand takes the blame.

Formulation Fit: Fruit Powder Is a System Component

Freeze-dried fruit powder interacts with acids, sweeteners, proteins, and tea solids. That interaction determines whether the drink feels smooth, bright, and clean, or harsh, muddy, and gritty.

In protein or smoothie blends, mouthfeel is more sensitive, so fine powders must be evaluated for chalkiness in the real base. In tea-fruit blends, bitterness and aroma hierarchy matter more than people expect. In clear-style drinks, sediment behaviour becomes the key risk.

When you want to educate buyers without overwhelming them, pointing to your technical library helps. Use Knowledge as the place to explore application notes and testing logic.

Expert Insights From People Who Fight These Problems Daily

A beverage technologist’s view: the only test that matters is the one that matches consumer behaviour. If your drink is designed for cold water and shaking, evaluate in cold water and shaking. High-shear lab mixing can hide the defects that show up in real use.

A quality manager’s view: many “ingredient failures” are actually handling failures. Even strong powders will clump if they sit open in humid rooms or are repeatedly exposed during production. Tight sealed handling and realistic storage checks are essential.

A product developer’s view: stability beats intensity in the long run. A slightly less intense powder that disperses smoothly and stays visually acceptable will outperform a “strong” powder that creates sediment, clumps, or batch drift.

How Fujian Lixing Supports Beverage Ingredient Selection

Fujian Lixing Foods Co., Ltd. specialises in vacuum freeze-dried fruits and vegetables, instant tea powder and tea concentrate, and other plant extracts. For beverage brands, the practical value is portfolio compatibility: fruit powders can pair naturally with tea-based systems, and both categories benefit from performance-focused evaluation.

For buyers who want the manufacturer background and capability context, use About Us. For sampling requests and application discussions, route to Contact Us so the conversation starts with your beverage type, preparation method, and performance targets.

Conclusion

For US beverage brands, freeze-dried fruit powder works best when it is selected like a performance ingredient, not a flavour shortcut. The powders that win in market are the ones that wet fast, disperse cleanly, look acceptable after standing, hold natural colour, and stay consistent across handling and storage realities. If you evaluate under real mixing conditions, treat humidity as part of quality, and match the powder format to your drink type, you’ll reduce formulation churn, avoid production surprises, and deliver a beverage experience customers trust—batch after batch.

FAQ

What is the best way to test freeze-dried fruit powder for cold drinks?

Test it in cold water at the real serving concentration using the real mixing method consumers will use, then check for clumps and sediment after 10–30 minutes of standing.

Why does freeze-dried fruit powder sometimes clump on the surface?

Clumping usually happens when the powder resists wetting or has been exposed to humidity. Fast-wetting powders and disciplined sealed handling reduce this risk.

What causes sediment in fruit powder beverages?

Sediment typically comes from insoluble fruit components or incomplete dispersion. Standing tests and recipe fit checks help predict whether settling will look acceptable to consumers.

Can freeze-dried fruit powder be used in tea-based drinks?

Yes. Fruit powders can layer aroma and colour into tea systems, but you should test flavour hierarchy so fruit supports the tea instead of overpowering or clashing with it.

How do I prevent gritty mouthfeel in smoothie or protein blends?

Evaluate powder fineness and dispersion in the real base, not just in water. Some powders behave well in water but feel chalky in protein systems.

What storage conditions help keep fruit powders stable?

Keep powders sealed, protect them from humidity and strong light, and minimise open-air exposure during production and handling. Moisture control protects flowability and consistency.

What information should I provide when requesting samples for a beverage project?

Provide your beverage type, serving temperature, mixing method, target flavour profile, desired colour intensity, and any stability expectations such as standing time and storage conditions.

How do I choose between fruit powder and fruit pieces for beverages?

Powders integrate flavour and colour quickly and are easier to dose consistently, while pieces add visual identity but can complicate texture and settling. Many drinks prioritise powder for consistency.