What US Importers Look For in Freeze-Dried Vegetables for Instant Soups

12 月-28-2025

What US Importers Look For in Freeze-Dried Vegetables for Instant Soups

Rehydration texture, flavour clarity, and audit-ready documentation—so your soup cups and meal kits stay consistent from factory line to consumer bowl.

The US Instant Soup Market Rewards Consistency, Not Guesswork

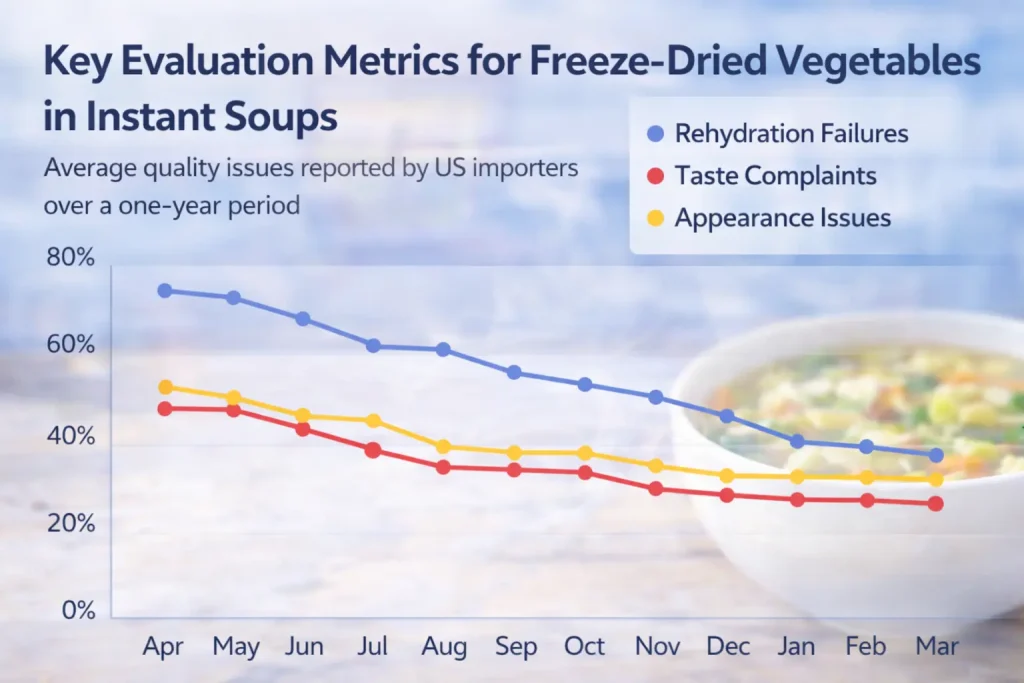

US importers buying freeze-dried vegetables for instant soups are not just sourcing “ingredients.” They’re buying performance. One inconsistent lot can create a chain reaction: uneven rehydration, dull colour, off-notes in aroma, customer complaints, chargebacks, and a very uncomfortable call with a retail buyer.

That’s why the best importers evaluate freeze-dried vegetables using a simple rule: the ingredient must behave predictably in the finished product under real conditions—short hydration time, boiling water variability, different bowl sizes, and consumers who never follow instructions perfectly.

If you want to browse a wide range of options first, start from the Dried Foods collection and narrow down by application and cut type.

What Counts as “Instant Soup” in US Buying Decisions

Importers usually group “instant soup” into several product realities, each with different ingredient requirements:

A cup soup or pouch soup must hydrate fast and look appetising within minutes. A meal cup (noodles + vegetables + protein) needs vegetables that do not turn mushy while noodles finish cooking. A “healthy” soup mix cares about visible vegetable identity and clean flavour, while a “value” soup mix cares about stable supply and consistent texture even when formula changes.

If your portfolio includes meal cups or noodle soups, it helps to understand how ingredient behaviour differs from traditional formats—use this reference for product-context linking: difference between freeze-dried and instant noodles.

The Performance Checklist US Importers Use (And Why It Matters)

Most importers use a checklist that prioritises real outcomes over pretty specifications. Below is the practical framework buyers use when they know what they’re doing.

Rehydration Time and “Ready-to-Eat” Texture

The first question is simple: does it rehydrate within the soup’s cook time? Many US instant soups are designed for quick preparation. Vegetables that require longer hydration force the brand to change the instruction time, which can reduce repeat purchase.

Texture is the next layer. The vegetable should rehydrate to a natural bite—not crunchy like undercooked, and not collapsing into a paste. For premium soups, buyers often specify a target “bite window,” meaning the vegetable stays pleasant even if the consumer waits a few extra minutes.

Cut Size and Visual Identity

Cut size determines everything: hydration speed, mouthfeel, and the visual “quality signal” in the bowl. Too small, and the ingredient disappears; too large, and it hydrates unevenly.

Importers often ask for size consistency because inconsistent cuts create inconsistent bowls. In the US market, consumers interpret inconsistency as poor quality even when the product is safe.

Flavour Clarity (No “Green Water” Problems)

High-performing freeze-dried vegetables should deliver clean vegetable notes without turning the broth muddy. Some vegetables, if poorly selected or processed, can release excessive pigments or create “green water” effects that look industrial rather than appetising.

A good importer tests vegetables directly in the finished seasoning system because seasoning, acids, and oils can amplify defects that seem minor when tasted alone.

Colour After Hydration

Colour is not decoration—it’s trust. In US retail, consumers expect vegetables in soup to look like vegetables, not grey fragments.

Importers typically test colour in two ways: immediately after hydration and after standing. If colour collapses quickly, the bowl looks tired before the customer takes the first spoonful.

Aroma and Off-Notes

Off-notes are a deal-breaker in instant soup. Common importer concerns include stale, oxidised, or “storage” aromas that appear after the product sits on shelf.

Because soups often contain strong seasoning, buyers test whether vegetable aroma stays clean under heat and whether it contributes to the final flavour instead of fighting it.

A Simple Application Table Importers Use for Ingredient Matching

US buyers often use a matching table to avoid format mistakes:

| Instant Soup Format | What the Vegetables Must Do | Typical Risk |

|---|---|---|

| cup soup (3–5 min) | hydrate quickly and look bright | under-hydration or hard bite |

| meal cup (noodles + veg) | stay intact without turning mushy | vegetables collapse during noodle cook |

| “healthy” soup mix | maintain visible identity and clean taste | dull colour, weak vegetable character |

| long-shelf retail packs | remain stable over time and shipping | flavour drift, texture inconsistency |

Food Safety and Audit Readiness: The US Importer’s Non-Negotiables

Even if performance is excellent, US importers will not commit without confidence in food safety systems and documentation quality. The strongest supplier relationships are built on predictable compliance work, not improvisation.

Buyers commonly look for established certifications and documented control systems. They also care about lot traceability and the ability to respond quickly with paperwork when a distributor, retailer, or third-party auditor asks questions.

If you want to present capability context in a way that feels professional and grounded, link to About Us within a paragraph that discusses manufacturing scale, R&D capacity, and certifications.

Shelf Stability and Handling: What Breaks Quality During Transit

Instant soup ingredients travel. They face long storage cycles and varied climates. Importers care about stability because defects often appear after distribution, not at the sample stage.

Moisture exposure is a common failure mode. Even strong freeze-dried vegetables can soften, clump, or lose aroma if packaging integrity is weak or if the ingredient is frequently exposed during repacking.

For content that supports your storage narrative, use a natural reference like “shelf life expectations” and connect it to shelf life of dried foods to keep readers inside your ecosystem.

Expert Insights

A US importer’s view: the most expensive ingredient is the one that triggers a recall-like response from a retailer, even when it is not a safety issue. Visual inconsistency and hydration failures can destroy trust faster than a small cost difference ever can.

A product developer’s view: you should test vegetables inside the actual soup formula, not in plain hot water. Oils, acids, and seasoning change the way colour and texture behave, and a powdery seasoning system can hide defects until the product is on shelf.

A quality manager’s view: audit readiness is operational confidence. When a buyer can get fast traceability and consistent documents, they are more likely to scale orders because they feel protected when something unexpected happens.

The Sampling Protocol That Saves Importers Time

A practical supplier evaluation usually follows a predictable sequence:

First, run hydration tests at the brand’s intended preparation time using real consumer behaviour (stirring level, standing time). Next, test in the finished formula, not just water. Then run a short stability check under likely storage conditions. Finally, evaluate documentation response speed: how quickly the supplier can provide standard supporting files and lot information.

If you want to educate buyers with a “how to evaluate” approach, route them to your Knowledge hub as the place where testing methods and application notes live.

Where Freeze-Dried Vegetable Soup Packs Fit in the Product Story

For many US buyers, the instant soup category is expanding into “complete solutions,” not just individual ingredients. Vegetable soup packs, pre-balanced blends, and application-ready formats help brands reduce formulation time and reduce variability.

If you want to connect this article to a relevant solution-style page, you can reference freeze-dried vegetable soup packets as an example of how freeze-dried components support convenient, clean-tasting soup formats.

Working With Fujian Lixing for US Instant Soup Ingredient Supply

Fujian Lixing Foods Co., Ltd. manufactures vacuum freeze-dried fruits and vegetables, instant tea powder and tea concentrate, and other plant extracts. For US instant soup buyers, the value is reliable supply matched to application needs—cut formats that hydrate predictably, stable appearance in the bowl, and a process foundation that supports long-term procurement planning.

When a buyer is ready to move from reading to sampling, the clean next step is Contact Us so the request can include the soup format, target cook time, desired cut size, and performance expectations.

Conclusion

US importers choose freeze-dried vegetables for instant soups based on performance and predictability: hydration time, natural bite, visual identity, colour stability, and clean flavour in the finished broth. Just as important, they choose suppliers who can support audits, documentation, and consistent lot control. When you evaluate ingredients in real soup conditions and treat stability and traceability as part of quality, you build a supply chain that scales smoothly—without surprise failures that show up after distribution.

FAQ

How do US importers test freeze-dried vegetables for instant soup performance?

They test rehydration time and texture in real preparation conditions, then repeat the test inside the finished soup formula and check how the vegetables look and feel after standing.

What cut size is best for cup soups?

Smaller, consistent cuts usually hydrate faster and fit short prep times, but the best size depends on cook time and the visual identity you want in the bowl.

Why do some vegetables turn the broth cloudy or “muddy”?

Certain cuts or processing conditions can release pigments or fine particles during hydration, especially when combined with seasoning oils and acids.

How can brands avoid mushy vegetables in meal cups with noodles?

Choose vegetables with a stable bite window and test them during the noodle cook cycle, including standing time after hydration.

What documentation do US buyers typically expect from suppliers?

They usually expect reliable lot traceability, consistent supporting documents, and fast response to audit or distributor information requests.

How can humidity affect freeze-dried vegetable quality?

Moisture exposure can soften texture, reduce aroma, and create clumping or quality drift during storage and repacking.

Are freeze-dried vegetable soup packs a good option for new product launches?

They can reduce development time and improve consistency because the format is designed for predictable hydration and bowl appearance.

What details should I include when requesting samples for instant soup development?

Include soup format, preparation time, water temperature assumptions, desired cut size, target texture, and any stability expectations such as standing time and storage conditions.